Reverse-Engineering

Reverse-Engineering (Board Prototyping, Testing and Retrofitting)

At Atya Technologies, we provide a Reverse Engineering of Printed Circuit

Board service. We have the capability to fully reverse engineer your

sample board, along with its components,

to produce all the

necessary data for replication. Our expertise even extends to reverse

engineering boards that contain programmed ICs, unique components, and

outdated parts.

Stages of Reverse Engineering

Stage 1: Schematic Design

Produce a circuit diagram from the sample PCB. From the schematic and sample PCB a full bill of materials can be produced.

Stage 2: Analyse the Original Design

Investigate the original design and check the original calculations to see if they were the possible design errors. Discuss with the customer any common failure modes they have experienced.

Stage 3: Redesign the Circuit

Redesign some parts of the circuit that are likely to lead to failure,

using modern techniques and components.

Review the input and output interfaces to see if they can be protected

from damage by other external circuit failures.

Stage 4: Analyse Components

Review the Bill of Materials used and check if they are recommended for new designs. After many years there are usually alternative semiconductors, which are more reliable.

Stage 5: PCB Design

Design a new PCB with industrial standard tools and apply the latest safety standards that are applicable to the product.

Stage 6: Sample Manufacture and Approval

Manufacture and test a sample PCB for customer approval. Required tests followed by formal approval and may be produced for assembly.

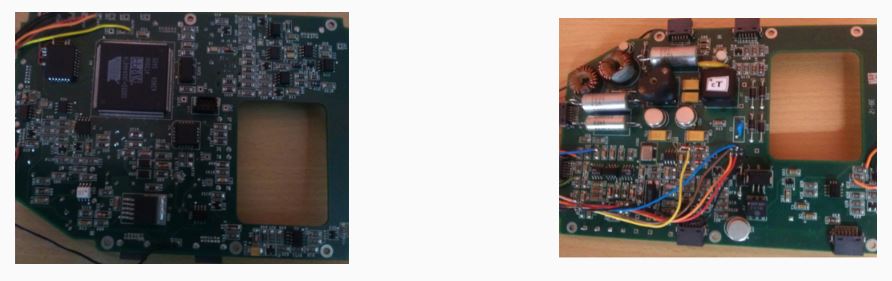

Case Study: Laser Range Finder

The Gunner's Main Sight is now equipped with a laser range finder, thanks

to the re-engineered Controller PCB provided by RTS through Bharat

Electronics Limited for CVRDE.

By updating the outdated board with

modern components, RTS was able to offer a Form, Fit, and Function (F3)

Solution that met all necessary qualifications.